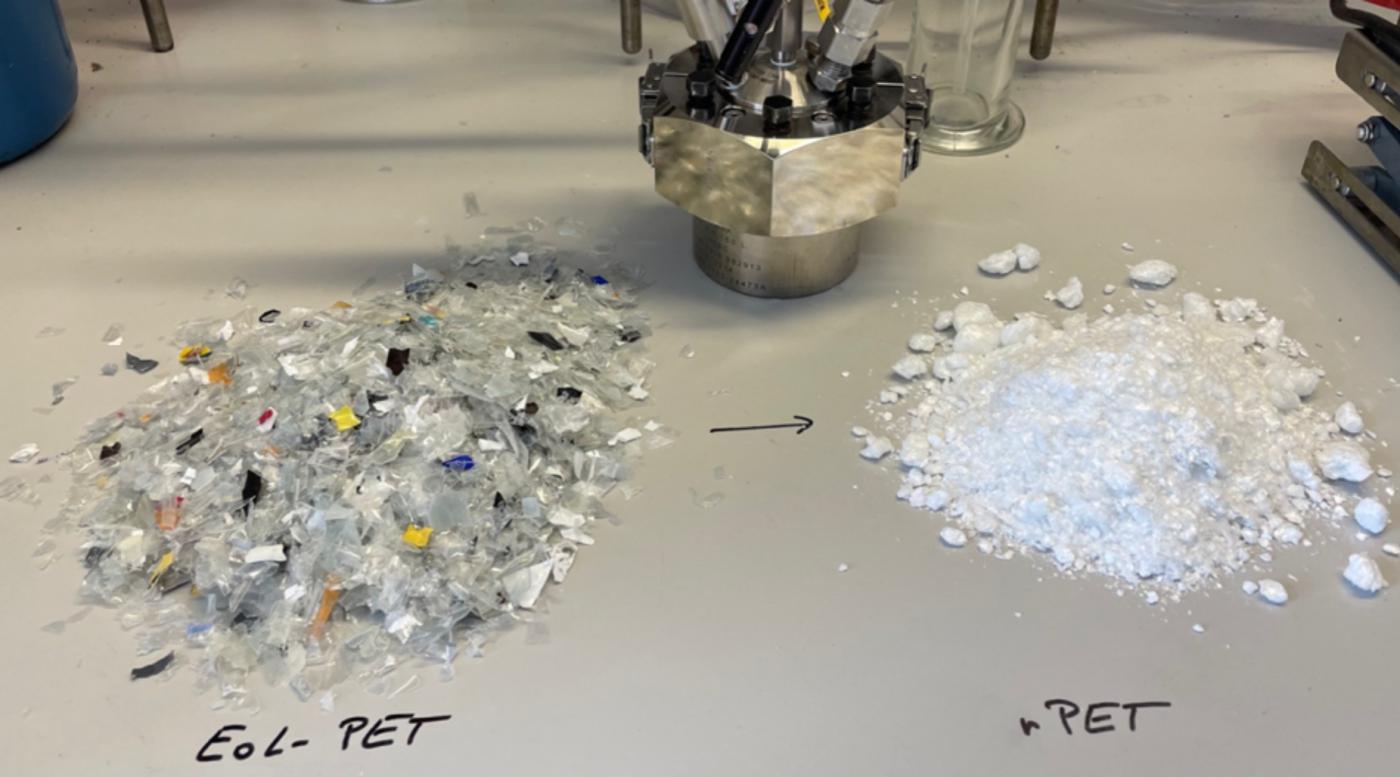

"Recycling PET mechanically is a tried and tested means of returning plastic to the cycle. However, it requires high-quality PET material. Unfortunately, more than 50 per cent of PET waste does not meet these requirements and is instead burnt and emits carbon dioxide," Enthaler pointed out. The "Chemical Recycling of End-of-Life PET as a Building Block of a Circular Economy" project aims to prove chemical recycling is the solution. PET waste is broken down into dimethyl terephthalate and ethylene glycol and converted into new high-purity PET during polymerization. Thus, the waste becomes a resource for new PET plastic material. Efficiency is improved and greenhouse gas emissions are avoided.

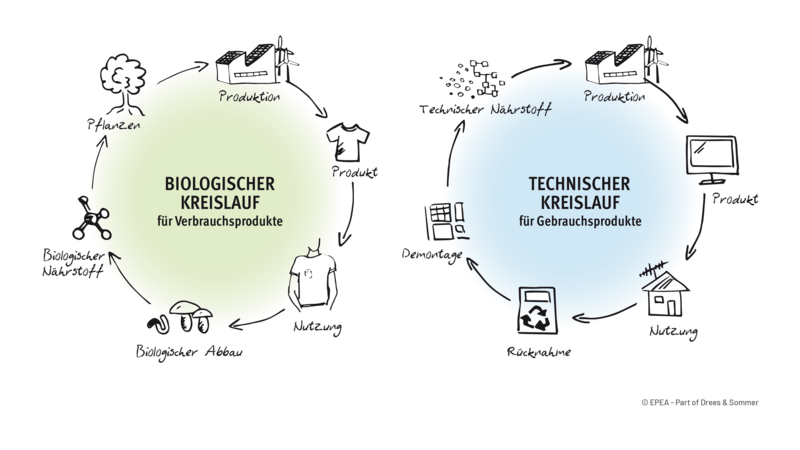

Recycling plastic packaging must be stepped up despite Germany’s recycling rate of 46.2 per cent in 2020 by European comparison and its pioneering role in developing a circular economy. "More than 500,000 tons of polyethylene terephthalate (PET) plastic waste per annum can no longer be recycled. That amounts to a loss of more than EUR 1 billion. New PET based on fossil raw materials are then used,” said Dr Stephan Enthaler, Institute of Inorganic and Applied Chemistry at the University of Hamburg (UHH) who is on a mission to change this dire situation with his colleague Dr Christoph Alberti. As part of the Calls for Transfer (C4T) funding scheme, the duo are researching an innovative, efficient means of turning non-recyclable plastic waste into new, high-quality plastics and returning them to the technical cycle.

"Chemical Recycling of End-of-Life PET" for circular economy

Potential of chemistry for the circular economy

The economic potential of the process did not go unnoticed during the Hamburg Innovation Awards 2022 and scooped first prize in the "Ideas" category. "Chemistry can potentially contribute to transformation from a linear to a more environment-friendly circular economy," Enthaler believes and drawing on 12 years of research into recycling plastics and over 20 years experience of catalysis research.

"PLA - Benign-by-Design" project

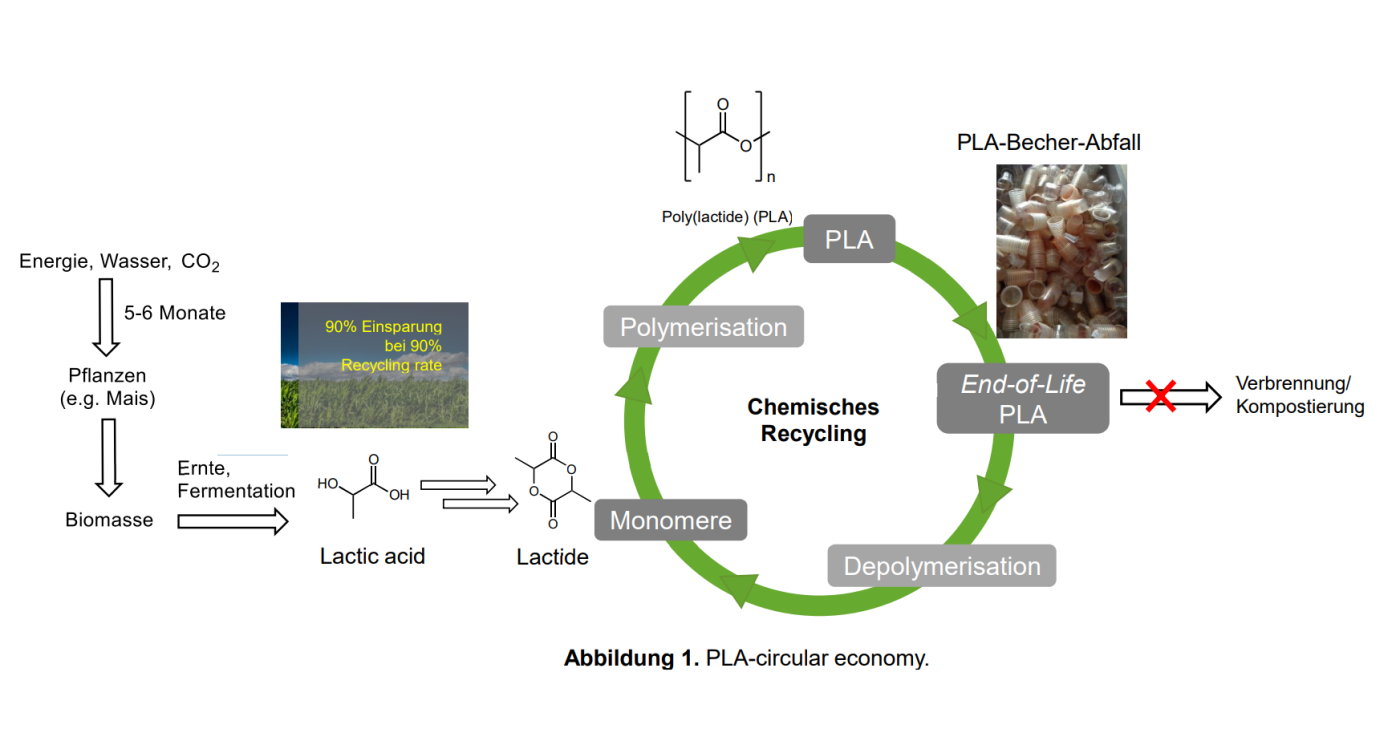

While the C4T project at the University of Hamburg focuses on the chemical recycling of PET plastic produced from fossil feedstocks, another C4T project focuses on polylactide plastic (PLA) based mostly on renewable raw materials. Professor Irina Smirnova, Dr Carsten Zetzl and Dr Mouna Kehili at the Hamburg University of Technology (TUHH) and Enthaler are researching ways of recycling PLA waste as part of the "PLA - Benign-by-Design" project. New smart PLA materials are also being produced the recyclability and sustainability of which have been considered from the outset.

Limited fossil resources

"The aim is to conduct a feasibility study for a special circular economy approach on an industrial scale," said Dr Mouna Kehili. The project also aims to create the conditions for a knowledge-based spin-off. The issue is expected to remain highly topical as the materials are lightweight, flexible, versatile and inexpensive to produce. "Worldwide, several hundred million tons are produced, used and disposed of every year, primarily on the basis of fossil resources," said Kehili. "The limited amount of fossil resources leads to a raw material gap in industrially-relevant components in the long term. Renewable resources are being mulled as an alternative source to meet demand and various processes have already been presented."

Processes on industrial scale

Enter the "PLA - Benign-by-Design" project with its focus on recyclability. The new carbon neutral and waste-free recycling process facilitates the controlled degradation of PLA waste to monomer lactic acid from which new high-purity PLA can be recovered. "The process can be integrated into established industrial production. Efficient PLA recycling relieves renewable resources," Kehili noted. The sustainable degradation process has been tested successfully in many research projects and should soon prove itself on an industrial scale.

ys/pb

Read the other parts in our series:

1) Calls for Transfer scheme funding tiny implants for cancer diagnostics

Sources and further information

- Calls for Transfer

- Institute for Inorganic and Applied Chemistry

- Institute for Thermal Separation Processes

Calls for Transfer

"Calls for Transfer" is funded by Hamburg's Ministry of Science, Research, Equality and Districts and is sponsored by the University of Technology (TUHH). The project is managed by Hamburg Innovation the board of which makes independent decisions. Hamburg Innovation GmbH is a private knowledge and technology transfer institution at Hamburg's public universities. At the interface between universities, companies and the public sector, the team networks entrepreneurial and scientific potential thereby creating sustainable value for science, politics, business and society.

More

Similar articles

Michael Braungart: revel in your ecological footprint!