© Hamburg Invest

Hamburg launcht neue Förderprogramme für Startups und KMU

Fokusthema: künstliche Intelligenz

Aktuelle Termine

Future Hamburg Talks

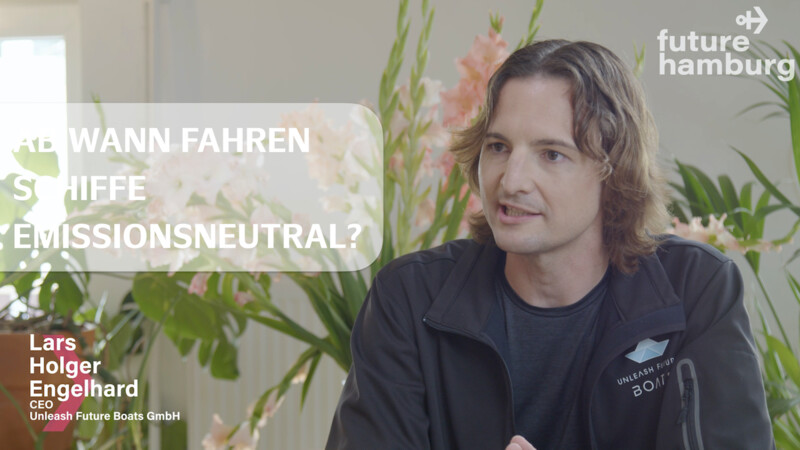

Future Hamburg Talk meets … L. H. Engelhard von Unleash Future Boats

Future Hamburg Talk meets … Sabine Winkler vom DeveLUP

Future Hamburg Talk meets … Jonathan Hendess vom Impuls Festival